Lew Rodert, Epistemological Liaison,

and Thermal De-Icing at Ames

by Glenn E. Bugos

A paradox in aircraft icing research took the National Advisory Committee for Aeronautics (NACA) further into actual aircraft design than it had ever before ventured, To gather data on new de-icing equipment under natural icing conditions, and do so safely, NACA needed an aircraft already invulnerable to the dangers of icing. So Lewis A. Rodert, leader of NACA icing research from 1936 to 1945, built his own de-icing system on two aircraft first a small Lockheed 12A and next a Curtiss C-46 transport that would become flying laboratories for further research. "Seldom before," wrote Edwin Hartman, NACA's representative in southern California and Rodert's liaison to aircraft manufacturers, "had NACA's research work been carried so far into the hardware stage or so far in achieving a complete and satisfying solution to a major operational problem."1

Yet when Rodert received his Collier Trophy in December 1947, the practicality of his innovation had hardly been established. As evidence of practicality, the press release noted only that his specially-modified C-46 flew through the weather that grounded other aircraft. Manufacturers had begun building similar de-icing systems, though few followed Rodert's suggestions. Still, despite the narrow practicality of Rodert's work, he was indeed largely responsible for getting industry off its duff. The Collier Trophy, given annually in recognition of outstanding achievement in aeronautics, testified to the peculiar and fruitful synergism of his personality with the NACA advisory committee form of research.

Rodert was a short, intense man, just forty years old when he won the award. Born in Kansas City and raised on a farm in Kansas, Rodert studied at the Kansas City Junior College before transferring and graduating with a Bachelor's degree in 1930 from the University of Minnesota.2 He instructed in aeronautical engineering at Duluth junior College in Minneapolis before moving briefly to Curtiss Aeroplane & Motor Company in Buffalo, New York. He joined NACA's Langley laboratory in 1936 to do de-icing work, transferred to the new Ames laboratory in California in 1941, quit briefly to join industry in 1946, then returned to NACA as chief of the flight research branch for the new Cleveland laboratory. The Flight Safety Foundation cited Rodert in 1953 for his "aircraft fire prevention research work" while at the Cleveland center, and his alma mater gave him the 1954 University of Minnesota Outstanding Achievement Medal. In 1956 Rodert joined Lockheed in Burbank, California, as a special assistant on research management, then quickly disappeared from the aviation scene. Former coworkers passed rumors of his decline into mental illness.

Rodert put everyone on edge with his show-me attitude. Rodert encountered many philosophies of de-icing, and accepted none easily. In the aeronautical research community rife with epistemological insecurities, where unequivocal proofs were the most exasperating part of any researcher's daily life work moved forward because peers conferred upon each other the initial benefit of the doubt. Rodert broke that unspoken rule by calling

29

30 LEW RODERT, EPISTEMOLOGICAL LIAISON, AND THERMAL DE-ICING AT AMES

|

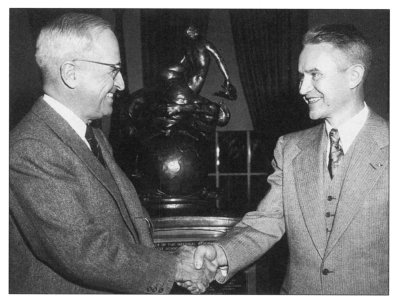

| Lewis A. Rodert, then, Chief of the Flight Research Branch at the NACA Lewis laboratory, was awarded the, Collier Trophy for 1946 for his pioneering work in the development and practical application of a thermal ice prevention system for aircraft. (NASA Photo) |

Rodert was no organization man. He was a poor manager. He did, however, expertly exploit the most fundamental structure of the NACA research organization its system of nested advisory committees. Committee business allowed him to visit with virtually everybody manufacturers, airlines, and military pilots to hash out the details of thermal de-icing. Furthermore, Rodert worked oblivious to the rarefied distinctions between basic and applied research that then gripped so many NACA officials, and that today guides so much historical analysis of the NACA. Rodert judged everything simply on how well it kept ice off an aircraft in flight. This study of Rodert's work, therefore, focuses on his role as epistemological liaison-on the practical work involved in establishing certainty for himself, and amongst the many groups mobilized to defeat the icing menace.

Defining an Approach

Following a joint Army-Navy request, in 1928 NACA researchers initiated a small-scale investigation of aircraft icing, then a big mystery as well as a big cause of aircraft crashes. First the NACA surveyed air mail and airline pilots on which aircraft were most likely to ice, and collected reports on crashes attributed to icing. They built a small six-inch refrigerated wind tunnel, the first icing research tunnel in the world, and watched how ice formed on an airfoil. And they installed a free-flight icing rig under the shoulder-mounted wing of an old Fairchild F-17 cabin monoplane. There they mounted a thermometer and a small but visible wing section, on which they sprayed water as the aircraft passed through freezing air.

NACA pilot William H. McAvoy, by just watching this wing section as ice formed, confirmed some suppositions about icing. Ice did indeed form "mushroom" shapes projecting forward of the leading edge, rather than smooth sheets coating the airfoil. Pilots should expect, McAvoy continued, that ice also formed on fast-turning propellers with mushroom projections. Ice that hardened far back on the wing posed no problems because it adhered poorly and slipped off easily. McAvoy also collected anti-icing pastes from the airlines greases and oils, and water soluble compounds like glycerin, honey,

FROM ENGINEERING SCIENCE TO BIG SCIENCE 31

Karo syrup, and soap but discovered these actually induced icing by trapping ice crystals until huge hunks formed. From his window-side survey of the state of the art in aircraft de-icing, McAvoy had established a way of studying icing-flight tests to frame questions about the impact of ice on aircraft performance.

NACA theoreticians Theodore Theodorsen and William C. Clay directed the tunnel experiments as part of a broader research program on turbulent airflow. By mounting an electrically-heated, brass wing section in the tunnel, and impregnating it with thermocouples, they showed that heat transfer between an airfoil and its atmosphere varied directly with airspeed and closely followed the pressure distribution of air along the airfoil. Local transmission of heat was high along the leading edge, diminishing to zero by the thirty percent chord.3 With this tunnel set up, Theodorsen and Clay also tried out some ideas on thermal de-icing that is, applying heat to melt ice as it formed. McAvoy also tested thermal de-icing on NACA's free-flight apparatus. NACA shops built a small metal airfoil, of four-foot chord and two-feet span, and mounted it under the Fairchild. Once ice formed, the pilots turned on a small boiler in the engine exhaust manifold and measured how much steam was required to keep ice from forming or to melt ice once it had.

As early as 1931 NACA had established the principle of thermal de-icing as strongly as doubts about its practicability. Theodorsen and Clay concluded that steam heat might de-ice wood-composite wings but the system would be "excessively heavy," especially if' designed to de-ice all the struts and support wires that then held together such wings.4 The best system, they suggested, would use waste heat from the exhaust stream, but this would likely await development of new all-metal monoplane aircraft. "The recommendation for the guidance of those who must encounter [icing] conditions," concluded McAvoy, "appears to lie entirely along the lines of their avoidance."5

On the last night of 1934, an aircraft slammed into an Adirondacks mountain killing its passenger and crew of four. The weather remained cold so that a crash inspector, curious that the aircraft had not burned, found the carburetors completely choked with ice. The engines likely just suffocated and stopped, leaving the pilot no way to de-ice and restart it. Publicity prompted the Commerce Department to investigate and discover that, during 1934, twenty-six planeloads of passengers had been forced down by carburetor icing.6 Some of the most disastrous crashes in aviation history had been attributed to icing, and airline executives widely believed that their industry would never boom until they erased this element of danger.

Pennsylvania-Central Airlines resurveyed its route system for winter flying conditions, raising some minimum ceilings and adjusting ranges. American Airlines improved their runways for winter operations, Northwest added staff for better flight and weather planning, TWA prohibited its pilots from landing when icing conditions prevailed below 1,000 feet, and United Airlines started paying their pilots a base salary in addition to flight pay so they would have no disincentive to cancel flights in bad weather.7 This winter, wrote all airline executive in December 1937, "is the best opportunity the industry has ever had to

32 LEW RODERT, EPISTEMOLOGICAL LIAISON, AND THERMAL DE-ICING AT AMES

demonstrate to the public that air transportation is more than reasonably safe." Their strategy: "cooperate with the weather in a big way."8

But airline operators and manufacturers ultimately wanted to defeat the icing menace, not cooperate with it. Aircraft already rivaled the steamship and train for speed and economy; but it lacked regularity. Radio navigation aids had brought aircraft to the brink of being all-weather conveyances, until the temperature dropped. Lacking a technological fix to icing these airlines cancelled or delayed flights an estimated one-tenth of all flights at first sight of icing clouds. Icing became a consuming challenge, to both airline economics and engineer pride. Lewis A. Rodert joined the NACA Langley Memorial Aeronautical Laboratory (LMAL) in September 1936, and teamed with Alun R. Jones to re-invigorate NACA's icing research with youth, stubbornness, and a fresh perspective on icing problems.

Ice caused aircraft to crash by adding weight and preventing the pilot from climbing above the icing clouds, so that the aircraft gradually lost altitude and slammed into the ground. That was how most people understood the danger of icing. Rodert and Jones started their studies by showing that icing seldom enveloped the aircraft with weight, but rather icing incapacitated small but crucial parts. As McAvoy had proved with his photos of mushroom-shaped ice projections, and as Rodert and Jones confirmed, ice accreted along the wing and tail leading edges disturbing lift and adding drag. Ice clogged the interstices of rudders and ailerons, preventing control and inducing buffeting. It changed the aerodynamic profile of the propeller, causing it to vibrate and exert less thrust per horsepower. It coated windshields, so the pilot flew blind. Ice made antenna wires oscillate and snap, and generated static that rendered useless most radio communication and navigation. It distorted pitot shapes, so that pilots got erroneous airspeed readings. And it clogged carburetors, suffocating the engine. Frequently, the pilot lost each of these systems engine, wings, control surfaces, indicators, radio, sight within minutes. With their lives at stake, pilots of ice-hindered aircraft had little time for the careful observations NACA researchers promised to make.

Using a DC-3 Mainliner loaned by United Airlines, in September 1937 Rodert and Jones glued sponge rubber to the leading edge of the wing, simulating ice formations, and showed how a small layer of ice had a big impact on lift, drag, and stalling.9 NACA headquarters authorized construction of a larger icing tunnel at Langley. LMAL technicians insulated the tunnel with a crude layer of kapok pulled from surplus Navy life preservers, and added an open tank of ethylene glycol cooled by dry ice as refrigeration. This tunnel worked well enough for Rodert to further chart the impact of ice on aerodynamic efficiency, and to prove that a full size wing section could be de-iced with exhaust heat.10 But Rodert lost patience with tunnel research as he learned that tunnel ice bore little relation to the natural ice he hoped to defeat.

The B.F. Goodrich Rubber Company ran a small icing tunnel in Akron, where they verified the pneumatic de-icer they had introduced in 1930. The pneumatic de-icer was it strip of rubberized cloth holding inflatable rubber tubes that attached to the leading edge of a wing or tail. When the pilot unexpectedly encountered icing, he shot compressed air into the strip, cracking the ice so that the wind stream swept it off. It worked well enough to become standard equipment on large transports by the late 1930s, but never well

34 LEW RODERT, EPISTEMOLOGICAL LIAISON, AND THERMAL DE-ICING AT AMES

enough that aircraft could deliberately fly into icing conditions. Rodert and Jones held the tenet that nothing restrict where aircraft could fly.

Rodert and Jones also claimed the rubber boots were in no way fail-safe. Pilots already knew they were not very clean-they ballooned with changes in air pressure or returned wrinkled on the smooth airfoil contour after inflating. In carefully controlled test flights Rodert discovered pneumatic de-icers worked in really very limited conditions. They seldom cracked ice cleanly, and the jagged edges more quickly accumulated lumps of ice. Furthermore, the pneumatic de-icer attached to the wing at ten percent chord, with strips that protruded into the airstream that further accumulated ice at the place most likely to disrupt lift. If a de-icer failed and a bullet hole through one shoe would destroy pressure in the whole system profile drag could increase 458 percent over an unprotected wing, putting the aircraft in greater peril.11 B.F. Goodrich failed to see danger in this, contended Rodert, because the ice created in their tunnel bore little relation to natural ice. Goodrich sprayed water in big drops, which created a smooth coating of glaze ice. Natural icing was more likely to be opaque, crystalline rime ice, created when very small supercooled droplets ran into a crystallizing structure like a wing. Any tunnel that verified the utility of the pneumatic de-icer caused Rodert to doubt the entire enterprise.

So Rodert and Jones kept their research in free flight as often as possible, and worked on thermal de-icing to replace the pneumatic boot. They built a more elaborate icing installation between the double wings of a Martin XBM-1 dive bomber loaned to NACA by the Navy. But rather than using a heavy steam boiler, Rodert and Jones diverted hot exhaust directly from the engine into the model section. NACA Engineer-Test Pilots William H. McAvoy and Lawrence A. Clousing flew the XBM-1 into cold air, turned on the water spray, and a camera recorded how quickly the ice melted away. By early 1938 Rodert and Jones were convinced thermal de-icing held great promise. Confirming their optimism were reports, leaked through Naval Intelligence from London, that the Germans had added heat de-icing systems to two production aircraft, the Junkers Ju.88 and Dornier 217E. 12 The Germans had first studied thermal de-icing in late 1920s, as had NACA, but had accelerated their research under the Nazi regime. With war on the horizon, and airlines still agitating about the icing menace, Rodert and Jones thought it high time to prototype a complete thermal de-icing system and test it in real clouds.

The Lockheed 12A

NACA headquarters, anticipating funding for icing studies, allowed the Langley Flight Research Branch to buy a twin-engine, all-metal Lockheed 12A light transport. Rodert got dibs on converting it into what NACA researchers traditionally built so well a sophisticated and dedicated testing facility, but in the form of a flying laboratory. The 12A would easily accept a "hot wing:" the wing outer panels held no fuel tanks, detached easily at the nacelles, and the engine exhaust stacks were close to the wing leading edge. Most important, the 12A was built by a company interested in staying on the forefront of icing

FROM ENGINEERING SCIENCE TO BIG SCIENCE 35

research. Lockheed vice president and chief engineer Hall L. Hibbard assigned the 12A modifications high priority.13

Rodert and Jones started with Lockheed blueprints to sketch a hot wing. They added a butterfly valve in the engine exhaust stack to divert hot gas (at 1500°F) into a four inch diameter tube, running close to the leading edge but insulated from the wing structure, and exhausting out the end of the wing tube. To cool the tube and improve heat transfer, an intake scoop sent fresh air around the tube, then through holes in the spar web into the wing structure, and exhausting out louvers at the aileron hinges. They repeatedly calculated wing strength, since heat weakened metal structures, especially one modified with new tubes and holes. By August 1939 the designs were ready, and NACA went looking for a sponsor.

The Navy BuAer (Bureau of Aeronautics) was so enthusiastic about the idea that they asked Rodert to make the modifications on a Navy production aircraft. Navy PBY patrol boats anchored off the Aleutian Islands had special icing problems. Waterplanes were not easily covered with protective tarps, so thick ice formed on them overnight. Splash during taxiing added more sheet ice. The Navy needed a de-icer with enough punch to knock this thick glaze ice completely off the wing, and Rodert's design promised to do so. But Rodert had the 12A blueprints ready to go; switching aircraft would deter him from test flights the coming winter. Further, NACA had no facilities for modifying seaplanes. So BuAer sent a draftsman from its San Diego depot to Langley in September 1939, and NACA engineers helped him modify their 12A blueprints to fit a Consolidated PBY-2 Catalina patrol boat. BuAer hired Rodert and Jones to draft specifications for the PBY-2, especially the heat transfer calculations that helped Consolidated define the thermal performance of the system. When the PBY-2 was ready for testing the following summer, BuAer offered Rodert a job. But Rodert stuck with the NACA, and tied his lot with its patrons in the U.S. Army Air Corps (USAAC).

The USAAC signed a job order for the 12A wings in November 1939. Major C.M. Cummings of the Equipment Branch at Wright Field had helped Rodert at several crucial stages, and supported his project without change. The United States, in any type of war, was vulnerable to two avenues of attack-by air over Alaska or Newfoundland-both with severe ice storms. Germany, Rodert later wrote, "has aircraft which can fly in almost any kind of weather, irrespective of icing conditions. There cannot be a possible defense against such aircraft without similar or superior equipment."14 American aircraft must be able to fly through any clouds; indeed pilots will likely seek protective cover in them. For $25,000, the AAC bought new wings and a modified windshield from Lockheed, and loaned them to NACA for research. While Lockheed fabricated the wings, Rodert and his Flight Research Branch prepared for a move westward.

NACA had already begun construction on the new Ames Aeronautical Laboratory adjacent to the Navy's Moffett Field on the flat bay lands near Sunnyvale, California. Compared to the humid air over the Virginia Tidewater, the cold Sierra Mountain air mixing with the warm, moist air rising off the San Francisco Bay made excellent icing conditions. Furthermore, Rodert had freed his research from wind tunnels, and by July 1940 the well-equipped shops and hangars at Ames were ready for his group. Test pilots McAvoy and Clousing ferried out an old North American O-47 they would use until the 12A was ready. Alun Jones rejoined them in January 1942, along with Carr Neel, an engineer who became increasingly involved in the work. Since the icing research was the first project at the new Ames laboratory, engineer-in-chief Smith DeFrance lent constant aid to his Ames Flight Research Branch.

36 LEW RODERT, EPISTEMOLOGICAL LIAISON, AND THERMAL DE-ICING AT AMES

McAvoy picked up the 12A with hot wings from Lockheed's Burbank plant on January 22, 1941. Back at Ames they flew it enough to be sure the heat did nothing to weaken the wing. Then they went hunting for ice.

During March and April 1941, McAvoy, Clousing, and Rodert took up the 12A almost everyday, scanning the horizon for ever more severe icing. United Airlines had compiled atmospheric data to help its pilots avoid icing on their routes; the Ames group used this data to seek out the ice.15 The Weather Bureau office at the Oakland Airport confirmed that they would find the best icing flying westward from Sacramento to Donner summit in the Sierras. George W. Lewis, director of aeronautical research at NACA Washington headquarters, had recommended that Rodert attach a two-foot long, unheated strut above the right wing. Thus, in one photo they could contrast the clean hot wing with the icing on the unprotected "tell-tale" strut. Lewis was delighted a few months later when he received his copy of the first report out of Ames Rodert, McAvoy and Clousing's "Preliminary Report on Flight Tests" "So I am going to celebrate by taking a copy over to Dr. Ames."16

While the icing over California was regular, that spring it was hardly

severe. To secure ever more dramatic photographs, the group ventured the

12A further north and east. On March 20, 1941, while flying through cumulous

clouds over Superior, Michigan, at 9,000 to 11,000 feet, with air temperature

at twenty-six to thirty degrees, they got pictures of three inches of ice

on the strut while the wing below, on only half heat, was clean. Icing

on the few unprotected parts turned so severe on a flight between Minneapolis

and Fargo that the 12A slowed thirty-five mph from just the added drag.

While flying northward along the Pacific coast, Rodert reported: "The airplane

was struck by an electrical charge which melted the trailing edge of one

propeller blade and the edges of the airplane structure

|

| The Lockheed 12A ice research airplane at Ames.

(NASA photo no. Ames ALL-1166). |

FROM ENGINEERING SCIENCE TO BIG SCIENCE 37

at several points." 17 The lightning strike grounded the 12A during a week of excellent icing conditions, but proved they were indeed flying into severe conditions. (McAvoy would win the 1943 Octave Chanute Award of the Institute of the Aeronautical Sciences, and Clousing the 1947 Award, for their test flying in severe icing conditions.)18

The drama, the photographs, the urgency all helped Rodert protect and expand his program from a number of competitors. B.F. Goodrich was working hard to improve their pneumatic de-icers. At the 6,288 foot summit of Mt. Washington in New Hampshire, Goodrich mounted a test wing like a weather vane so it stayed in constant wind. There a design team tried out new de-icers with hundreds of smaller, self-sealing inflatable tubes, snap-action distributor valves, flexible camouflage sprays, water-repellent rubbers, and nonadhesive sprays like the silicone Icex19 As a result, pneumatic de-icers remained in wide use and the long wing span of the Douglas C-54 transport was the widest ever during and well after World War II.

Others preferred new chemical de-icers. Chemicals worked in two ways. Alcohol-based fluids lowered freezing temperatures. Other slick, oil-based fluids, exuded from wing leading edges or sprayed on before Take-off, prevented ice crystals from adhering to the wing surface. The British especially advocated chemical de-icing. They claimed Americans like Rodert were misled about the war dangers of icing by inaccurate reporting of early Royal Air Force raids over Germany. As far as the RAF was concerned, chemicals sprayed easily onto any aircraft, lasted for a complete mission, and kept off North Atlantic ice. The Royal Aircraft Establishment at Farnsborough was perfecting a Dunlop strip which leaked a steady stream of chemical along the wing during longer flights. Chemists at the Naval Research Laboratory, looking for quick relevance on U.S. entry into the war, concocted similar anti-icing pastes and fluids. Since Rodert had the only aircraft known to withstand icing, they regularly asked him to try out new fluid recipes. It was highly likely icing conditions over the North Atlantic differed from those over North America, Rodert concluded, but all fluids tested poorly. Perhaps the British realized this too, because they increasingly cancelled icing-bound flights out of distrust of their equipment. For the first three years of the war, in a period of otherwise exceptional technical cooperation, British and American icing researchers kept their distance. Farnsborough transferred the two-engine Bristol bomber they used for icing research to Ottawa in April 1941, and for most of the war the Allies communicated only through the National Research Council of Canada.

The Ames group reported some important discoveries in the spring of 1941 that confirmed the value of thermal de-icing.20 Most important, the heat required in free flight was much less than indicated in wind tunnel tests. A seventy-degree rise over the ambient dry-air temperature at 200 mph was enough to weaken the bond between the ice crystals and the wing (though a 100º F rise had a safer margin). Furthermore, heat concentrated on the leading edge-less than ten percent chord-was enough to protect the trailing parts of the wing. Thus, exhaust heat never weakened the wing structure.

NACA also reported how much heat would damage the structure. Lockheed had designed another "cellular" wing, which passed exhaust gas through large chambers directly on the leading edge with no additional cooling air. Lockheed volunteered to rig the wing with 107 thermocouples, far more than specified, to get information on how evenly it transmitted heat. When flying the cellular wing near Ames in July 1941, McAvoy had applied only partial heat when expansion at the leading edge caused buckling aft of

38 LEW RODERT, EPISTEMOLOGICAL LIAISON, AND THERMAL DE-ICING AT AMES

the rear shear beam, threatening destruction of the aircraft.21 Ames quickly replaced it with the exhaust tube wing, having just learned the upper limits of wing heating. This information was directly useful to the firms that designed and built aircraft-whom NACA referred to by the venereal term "the manufacturers"and they requested a great many copies of Rodert and Clousing's flight test reports.

To fly into ice clouds and survive, the Ames group necessarily became expert on the impact of ice on the total aircraft. "I am surprised to find," noted Engineer-in-Chief Smith DeFrance, "that there are so many details which have not been anticipated before the de-icing tests were started ."22 Frosting prevented photographs out cabin windows; Clousing and McAvoy found they needed better instruction on flying blind; electrically-heated pitots looked clean even when ice in the throat skewed pressure readings; exhaust gas corroded the aluminum alloy at the wing tip; and the radio broke regularly. Rodert persuaded United Airlines to install in the 12A a radio they had specially adapted for ice flying. He asked the Massachusetts Institute of Technology (MIT) to design electric-resistance heating for the twenty-five foot long antenna wire that stretched between the cabin and the tail. And he asked the Naval Research Laboratory and the Air Corps labs at Wright Field to design loop antennas that would not collect static as they encountered precipitation. Any sharp corner or gadget protruding into the airstream, Rodert constantly reminded manufacturers, was an invitation both to icing and static electricity.

In less than a year of flight testing on the 12A, and early experience with the Navy PBY-2, thermal deicing looked promising. Manufacturers kept pressing Rodert for more details on the 12A installation, which Rodert preferred to deliver in person rather than through reports. Rodert knew manufacturers could improve upon his 12A design especially in reducing weight by better integrating the tube into the wing structure-and thought being vague about details might prompt them to innovate. Rodert instead claimed expertise in flight testing. The NACA Special Subcommittee on De-icing Problems, which served as Rodert's peer review group, and from which he often sought advice on how best to report data, encouraged this division of labor.

The Subcommittee did not actually convene until April 1941. Rodert was

not initially a member, though its charge was to "help in keeping the research

organization in touch with the practical problems that require attack by

research."23 Early committee meetings

would have likely exasperated Rodert: just a bunch of guys sitting around

talking about icing. They freely dispensed fragments of experience, ill-formed

ideas, and random observations, and passed resolutions on which isolated

aircraft parts most needed Rodert's attention.24

They collected and amended dozens of letters:

My dear Doctor.- The industry is yelling to beat the band for a windshield that they can see through in rain and ice. Is there anyway you can expedite your activity on your improved windshield?25

But the committee gave a free hand to NACA's research bureaucracy,

and it gave a free hand to Rodert, to integrate and prioritize these requests.

FROM ENGINEERING SCIENCE TO BIG SCIENCE 39

But Rodert found allies among the committee chairman. He had met J.W. Tomlinson in 1939 when Tomlinson was on the NACA aerodynamics committee and vice president of engineering for Transcontinental & Western Airlines of Kansas City. Tomlinson had seen the Ju.88 on a trip to Germany and, even though he had a predisposition toward the rubber de-icers used on his fleet, he understood what Rodert was working toward. And Tomlinson kept writing Rodert letters of introduction and beating the bushes for icing tests. Tomlinson was called to active status with the Air Primary Training Command in April 1942. His last act as chairman was to meet with Disney Studios to have them make an educational film to effectively register" the icing issue in the minds of young servicemen.

Karl O. Larson became subcommittee chairman in 1942 and shifted its aegis from the NACA Committee on Aerodynamics to the Committee on Operational Problems. Yet Larson supported Rodert's desire to just make and verify ice-invulnerable aircraft, and not approach icing as an operational problem. Larson was chief engineer for Northwest Airlines which, like all airlines during the war, had subordinated passenger travel to military transport. Northwest's biggest military contract came from the Air Corps Ferry Command to run the "Alaskan air-way" between Minneapolis and Fairbanks. Flight experience taught Larson that the route was a natural and reliable icing laboratory. He assembled at the Minneapolis municipal airfield, near Northwest's headquarters, the equipment and technicians needed to keep aircraft flying through ice clouds.

Rodert, Clousing, and McAvoy had already talked of setting up flight test operations in the north, central states. They wanted a new base with reliable blasts of arctic air, light traffic, and no mountains for when they flew blind, and freezing air at ground level so they could photograph ice on the aircraft underside after it landed. Both Clousing and Rodert knew Minnesota Rodert from his years at the University of Minnesota and knew Minneapolis offered all that.

Larson converted an NACA Committee for the Winter Flight Laboratory in June 1942, which proposed that the Air Corps give Northwest a $55,000 contract to provide NACA with an office and access to Northwest facilities and personnel.26 Northwest managed operations and maintenance, while NACA directed a cooperative research project. The Ice Research Project opened in November 1942, and that winter hosted more than ten visitors per week in addition to the seven pilots and seventy-five mechanics on duty. Airlines and manufacturers were invited to send engineers with new equipment to test. The Weather Bureau sent a meteorologist to collect data and develop hypotheses on which atmospheric conditions caused icing. The Air Corps remained hands-off, to avoid duplicating operations at its existing Cold Weather Test Station at Ladd Field in Fairbanks, and sent only pilots from Wright Field, Ohio. Their task, however, was crucial: to fly thirteen aircraft with new de-icing equipment, including the first aircraft de-iced by heated air.

Heated Air De-Icing

Rodert had formed some negative opinions of heated air that is, chemically normal air as opposed to burnt exhaust gas with its attendant carbon gases and water and gas vapors. While trying to complete thermal de-icing of the 12A in late 1939, without resorting to convoluted ducting, Rodert had canvassed industry for a heater to put remotely in the tail. Stewart-Warner sold a gasoline-burning heater, for automobiles, that put out 8,500 BTUs per hour. Rodert asked if they might upgrade it to put out 75,000 BTUs, with less weight and very cold air intake. Stewart-Warner proposed linking ten burners together,

40 LEW RODERT, EPISTEMOLOGICAL LIAISON, AND THERMAL DE-ICING AT AMES

but could not get it to Rodert in time. So that winter he put a pneumatic de-icer on the 12A tail. He tried again the following summer, starting with a gasoline heater CurtissWright used for cabin heating. It too proved weak, so Rodert built a long exhaust duct to prove the concept of thermal de-icing in the tail.

Rodert had better luck using heated air to de-ice the 12A windshield. The Pittsburgh Plate Glass (PPG) Co. helped Ames find a laminated safety glass that conducted heat well, and mount double-panes with a 1/4 inch gap through which heated air flowed. Putting exhaust heat into the windshield was unsafe-seepage would dump toxic gas into the pilot's face, and Rodert wanted to hinge the inside pane so the pilot could move it out of his line of sight in warm weather. Rodert found that air diverted from the cabin heat exchanger was warm enough to keep the windshield free of ice, yet cooler than the critical temperature of the plastic binders. As early as November 1941 Rodert flatly contradicted Boeing's public thinking that much higher heat was required, and pronounced that, at an airspeed of 150 mph, only 1,000 BTUs per square foot per hour was needed to keep any windshield at 50ºF, and thus free from ice. United Air Lines liked the PPG windshield well enough to retrofit it onto all its DC-3s.27

Manufacturers were simply afraid of exhaust gas. A bullet hole or weakened seam could poison the cabin (though Rodert designed airflow to exhaust out the wing). A failed engine would send raw, explosive gas vapors into the wing tube or gasoline leaking front a wing tank might ignite against the hot tube (though Rodert claimed the wing got no hotter than if left parked in a tropical sun.) Exhaust gas corroded aluminum and manufacturers refused to take the weight penalty of using stainless steel, as Rodert had done on the 12A. In addition to the dangers of exhaust gas, de-icing the entire aircraft with heated air held some advantages. Manufacturers could couple heated air ducting more neatly with the skin, saving the weight and strength penalties of the exhaust tube. Heated air could be vented out small holes on the wing surface with minimal drag. And a steady source of heated air could provide the cabin comfort all aircraft then lacked. The problem, however, was finding a steady source of heated air.

Rodert turned his full attention to heated air in September 1941, after learning the Glenn L. Martin Company would use a cabin heater to de-ice the wings of a B-26. Since manufacturers accepted only heated air de-icing, Rodert planned to stay one step ahead of them. He toured plants in January 1942 and, after telling manufacturers de-icing required less heat than previously thought, now he had to tell them their heat exchangers were too weak. To prove this point, in April 1942 Ames again modified the 12A wings putting corrugated ducting on the right wing and sheet ducting with baffles on the left-to concentrate heated air on a narrower chord of the leading edge. Ames craftsmen built a cast aluminum heat exchanger that transferred heat from the exhaust stream into fresh air flowing to the wings. They also built a variety of heat warning and dump valve controls.

To take advantage of this expertise and to "relieve industry of the design and development work," the Army Air Forces (AAF) asked Ames to build a complete heated air de-icing system to retrofit into the Consolidated B-24D Liberator.28 The B-24D was a high-wing, four-engine heavy bomber which would have a long production run. The system would include hot wings and tail, an electrically-heated antenna, air alcohol-based windshield wiper, air anti-static system for the wings and antenna, and a carbon monoxide indicator for the

FROM ENGINEERING SCIENCE TO BIG SCIENCE 41

cabin.29 Heated air would exhaust through half-inch holes along the top wing surface, and then travel backwards with the boundary layer. This satisfied AAF specifications that the wings got a 70ºF temperature rise over the forward 20 percent of chord and a 20º F rise back to 75 percent chord. Engineers for the AAF Materiel Command approved Ames' blueprints, and in May 1942 Ames acquired B-24D No. 111678 (soon redesignated the XB-24F-CO). The Ames erection shop procured all materials, metals and fasteners, built the wing tubing, and installed it into the aircraft. Consolidated sent senior engineer Howard F. Schmidt and several draftsmen to Ames, who completed production drawings as the work progressed. As early as June 1942, the B-24D did well in test flights around the Bay area. Rodert declared he had standardized a work outline for retrofitting de-icing into existing aircraft, and was willing to take on more. Then problems arose with the heat exchangers.

Ames had bought exchangers from two exhaust systems specialists AiResearch Manufacturing Company of Los Angeles and Solar Aircraft Company of San Diego. They were stock designs, scaled up for greater output than ever achieved in an aircraft. When they failed, Ames commissioned other firms to submit prototypes AiResearch offered a different hollow-finned exchanger, Hardon & Wilson Company sent a pin-type exchanger, and Stewart-Warner Corporation offered a multiple-fin type exchanger that delivered the required BTUs but buckled under the blast and heat of the exhaust stream. Once word got out of Rodert's quest for an exchanger for a mass-produced bomber, Ames was swamped with prototypes. The Ames erection shop designed a few themselves, applying their new expertise in brazing compounds, metal conduction, and pressure drops.

Rodert's entire plan hinged on getting a workable heat exchanger, and he was confident he could find one. The German Ju.88, after all, had used heat exchangers a series of four along a single exhaust stream and Rodert heard reports that the Germans had also put similar exchangers on the Ju.52, Ju.188, Ju.388, and the four-engine Ju.290 search bomber. Rodert considered the Ju.88 "a splendid de-icing system" and got Wright Field to send him sections of the Ju.88 exchanger, now on the scrap heap, so he could look for some secret the drawings didn't convey.30 Rodert also wrote to Martin, asking for exchangers Ames could not duplicate from blueprints. It was common, Rodert discovered, for an exchanger's actual and predicted performance to differ as great as four times. Ames made a flying test bed out of its C-47 and, in their desperate search for a Workable exchanger, Ames pilots carried aloft thirty-two different designs during the summer of 1942. Once. trial and error indicated which exchangers promised results, Jones or Neel drove a batch across the Bay to the Berkeley laboratory of L.M.K. Boelter, where Ames bought analytical insight.

Boelter, a professor of mechanical engineering and associate dean of engineering at the University of California, was the sort of teacher who kept perpetual office hours. As a student, Jones had worked with Boelter on an earlier NACA contract seeking advice on placing thermocouples to study heat transfer along the wing surface. Boelter read widely-even translating articles on treat exchanger theory from Italian and German-and was fascinated with the process of perfecting equations to predict real-world performance of heat transfer systems. Boelter also understood the challenge of measuring tiny drops of airborne water from his tests of evaporative cooling towers. So Jones learned much from his free-ranging conversations with Boelter, though their mission at hand was perfecting airborne heat exchangers.

Ames asked Boelter to expand his group that summer of 1942 to run bench tests on all promising heat exchangers. Boelter's goal was to measure static pressure drops and

42 LEW RODERT, EPISTEMOLOGICAL LIAISON, AND THERMAL DE-ICING AT AMES

|

| A cutaway display model of a wing leading edge with a corrugated inner skin to direct heated air (NASA photo no. Ames A-10079). |

rates of heat transfer, devise a theory of exchanger performance, perfect all equation of design parameters so that predicted values approached measured performance, and ultimately offer to a single number for ranking exchanger performance.31 Rodert and his AAF patrons knew any number would be riddled with error, but hoped that Boelter could simply standardize the errors-in thermocouple placement, pressure drop and conductivity measures, and BTU output-so that it would still help in comparative rankings. Boelter's work on aircraft heat exchangers was widely praised, as the sort of analytical work Ames should have done on all facets of its icing research . 32

FROM ENGINEERING SCIENCE TO BIG SCIENCE 43

The British began following progress in heat exchangers, and softening their allegiance to chemicals, under the guise of better flame suppression. British bombers lit up at night because flames shot front their exhaust stacks as the hot exhaust ignited the fresh air. By moving heat into the wing tube, and thus cooling the exhaust stream below 1300º F, a heat exchanger prevented this re-ignition and torching. The U.S. Navy confirmed the prospects of flame dampening, by noting that its PBYs could fly only 200 feet over an aircraft carrier, at part throttle, without being detected. The Royal Aircraft Establishment (RAE) representative to the Ice Research Project, J. K. Hardy, began following Rodert's work, offering a good dose of skepticism that helped NACA refine its reporting.

General Electric's supercharger engineering department, which built turbochargers powered by the exhaust stream, invited themselves to standardize exhaust instrumentation. Their concern shared by the Army Air Forces was that putting a heat exchanger in the path of air exhaust stream pulsating at seventeen cycles per second might back up the flow of gases through the engine and impede engine performance. So as the summer dragged on and the BTU output of the exchangers steadily improved, Rodert turned his attention to ram pressures at the air intake scoop and pressure drops on the wing side of the exchanger.

By September 1942, the Ames group had approved five exchangers rated around 300,000 BTUs per hour that did not greatly diminish the range and speed of the B-24D. They weighed only thirty pounds, occupied a cylindrical space eight inches in diameter and twenty-two inches long. The complete de-icing system weighed an acceptable 300 pounds, less than 1.5 percent of the total gross weight of the aircraft. Pneumatic de-icers protecting only the wing and tail leading edges, weighed in at 230 pounds. As soon as the B-24F was out the door and on its way to Minneapolis following a brief inspection stop at the Consolidated Plant the Army Air Forces delivered to Ames a Boeing B-17F Flying Fortress.

Ames drew from their work on the B-24F to quickly retrofit de-icing equipment onto the larger B-17E. They started with the same heat exchangers, then modified those that buckled under the greater heat blast. Unsure of which exchangers would least impact range and speed, the B-17F carried an older exchanger designed for cabin warming in one nacelle and a proposed production exchanger bought from McQuay, Inc., the Trane Company, and AAF engineers at Wright Field in each of its other three nacelles. The Ames group tested pressure distribution around the exchangers well into the fall of 1943. They installed additional thermocouples, and tried out some valves to adjust heat flows from the four engines around the wings. By January 1943, Ames and visiting Boeing draftsmen had prepared corrected B-17F production drawings, and the aircraft was ready for icing tests in Minneapolis.

That same month, Ames outlined "preliminary design considerations" for the most complete deicing system yet, for a Curtiss-Wright C-46 Commando transport. The Army Air Forces, impressed with the plans, delivered to Ames C-46 No. 41-12293 in March 1943, once the Ames group returned from Minneapolis. As Rodert and Jones struggled to write up the B-17F and B-24D test results that manufacturers clamored for, they turned their attention to the C-46.33 The C-46 was then America's largest transport, much bigger than the B-17 and B-24, with a stressed wing that required more careful revisions and a long series of mock-ups. Ames built and tested two wing inner skins-with baffles on the right wing and corrugation on the left. Because the C46 was to be an all-weather aircraft, Ames had to protect the propellers, windshields, antennas, carburetors and

44 LEW RODERT, EPISTEMOLOGICAL LIAISON, AND THERMAL DE-ICING AT AMES

other parts vulnerable to icing. The wider radius of the C-46 propeller, especially, demanded a new approach to de-icing.

Ames had closely followed innovations in these other parts, but now Rodert had to make specific recommendations. Rodert's committee especially urged him to move forward: "The consensus of the subcommittee is that the thermal method of aircraft de-icing has been proved to be sound."34 Rodert should now help pilots follow the one rule bold-faced in every manual on de-icing: "You must maintain your airspeed ."35

Propellers and Carburetors

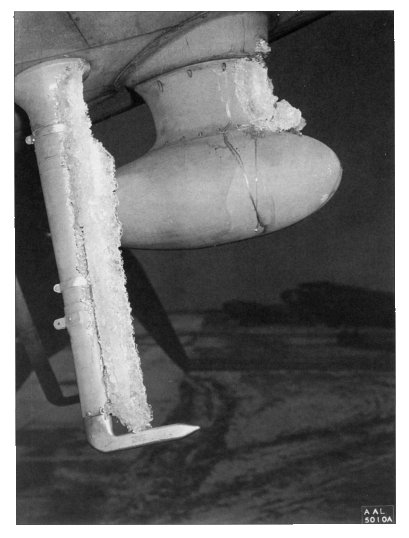

Rodert's work with propellers, as with wings, started with proof that de-icing was crucial, then showing how it was easier than previously thought. By stopping and feathering propeller blades in flight, Rodert, Clousing and McAvoy discovered how propeller icing usually started with a thin pencil of ice formed at the aerodynamic dead-center of the leading edge. Rodert's position that this pencil was a necessary precursor to de-icing proved controversial. A slight temperature rise weakened its attachment enough that centrifugal force spun it off, whereas a great amount of heat was needed to prevent it forming. Yet manufacturers claimed the pencil induced vibration as it unbalanced the propeller, and became a flying missile when spun off.

Chemicals also weakened the pencil adhesion, and their use dominated

propeller de-icing. Hamilton Standard offered viscous Icelac, the

British their Mark F9 Kilfrost paste, and the Naval Research Laboratory

their P-85 paste which absorbed ice crystals on a tacky, glycerin-like

surface before sloughing off the propeller.36

Slick lacquers like one developed by MIT kept ice crystals from adhering

to the propeller surface. Or a steady stream of alcohol expelled from a

slinger ring at a propeller hub and directed along a slotted

|

| The Custiss C-46 flying ice-research laboratory at the Ice Research Base. (NASA photo no. Ames ALL-3895). |

FROM ENGINEERING SCIENCE TO BIG SCIENCE 45

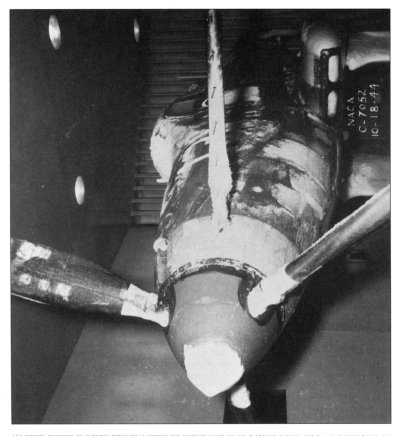

|

| An nacelle assembly in a Lewis Laboratory tunnel test showing icing on the propeller, October 18, 1944. (NASA photo no. NACA C-7052). |

rubber panel, cooled the icing temperature.37 None of the chemicals, however, worked longer than an hour. The lacquers pitted and eroded; the pastes sloughed off the faster propellers too quickly; the alcohol tanks depleted if used prophylactically. A three-blade propeller used three quarts of alcohol per hour, and manufacturers hesitated to put reserve tanks of highly-flammable fluids near engine nacelles. To improve de-icer fluid

46 LEW RODERT, EPISTEMOLOGICAL LIAISON, AND THERMAL DE-ICING AT AMES

economy, Monsanto tried to develop trimethyl phosphate used in automotive antifreeze as a universal deicing fluid for all parts of the aircraft. Still, the slotted surface that directed fluids over a propeller disturbed its aerodynamic efficiency.

So during 1942, Rodert turned his attention to thermo-electric blade shoes hard, neoprene strips imbedded with high-resistance wires and built into the leading edge of the propeller blade. The group assembled at Minneapolis that winter especially engineers from Ames, Wright Field, the National Research Council of Canada, and the Hamilton Standard Propellers Division of the United Aircraft Company verified the proper size, span, and heat output of the shoes. (Goodrich sent engineers to test a proprietary shoe but, in order to protect their trade secrets, kept on the outskirts of NACA-led studies.) As with heated air deicing, the biggest problem was adequate power. They had to match the shoe with a generator built into the propeller hub-too big a generator drained engine power, too small left the shoe underheated. In an April 1943 report, Rodert offered no theory of how to determine the right quantity of heat, but suggested some empirical rules of thumb: an optimum shoe span over twenty percent chord, along ninety percent of blade radius, and a hub-generator putting out 2.5 watts per square inch. Generating the five kW needed for complete protection of the B-17 sapped twenty-eight horsepower from the four propellers, and added 120 total pounds. The AAF committed to thermo-electric boots for its medium-sized bombers, but had Ames keep working on a better de-icer for the C-46.

The larger radius of C-46 blades made it impractical to heat a boot that long with existing hub-generators. Since the larger blades were hollow, Ames and Curtiss-Wright engineers proposed pumping heated air into the hollow blades, circulating it through baffles to better transfer heat to the surface, and ejecting it out the tips. Though the exhaust tips imposed no special drag, these engineers failed to devise a method for getting enough hot air into the propeller core. (Researchers at Cleveland experimented with burning fuel inside the core to generate heat.) NACA also tried internal electrical heating, running the resistance wires along the inside surface. In the end, the C46 left for Minneapolis with external thermoelectric boots and a promise of smaller and lighter hub-generators, which soon followed.

Rodert likewise had to recommend a system for de-icing the carburetor. Three types of ice can silence an engine. Impact ice forms around the air intake or ducting to the carburetor as supercoolled moisture hits a crystallizing surface. Throttling ice encrusts the interior surface of the carburetor, when moisture-laden air expands rapidly. Fuel-evaporation ice clogs the passageways to the cylinders, when vaporizing gasoline robs heat from air in the carburetor. Since throttling and fuel-evaporation ice forms whenever the air holds moisture, regardless of temperature, research into carburetor icing proved quite complicated.

As an interim precaution, the Civil Aeronautics Authority (CAA) specified that passenger aircraft have pipes to return hot exhaust into the air entering the carburetor, which could melt all three types of ice. The Ames group were satisfied that hot air return on their 12A would keep their carburetor invulnerable. But hot air pipes had weight, and because the hotter air burned less efficiently than cooler, denser air, pilots used it only when they suspected icing. In July 1940 the Engineering and Maintenance Committee of the Air Transport Association of America passed a resolution urging NACA to expedite research into carburetor de-icing.

So the NACA convened a Special Subcommittee on Induction System Icing under the Committee on Power Plants (it remained separate from the Subcommittee on De-icing Problems). Rodert was not a committee member, but they asked him to tour engine testing tunnels at Wright Field, Wright Aeronautical, Goodrich, Pratt & Whitney, and the Naval Aircraft Factory and find one for the induction tests. Rodert was most impressed with the carburetor test box at the Naval Aircraft Factory. But it was booked doing expedited production testing, as was every facility save the old altitude chamber of the National Bureau of Standards (NBS).

FROM ENGINEERING SCIENCE TO BIG SCIENCE 47

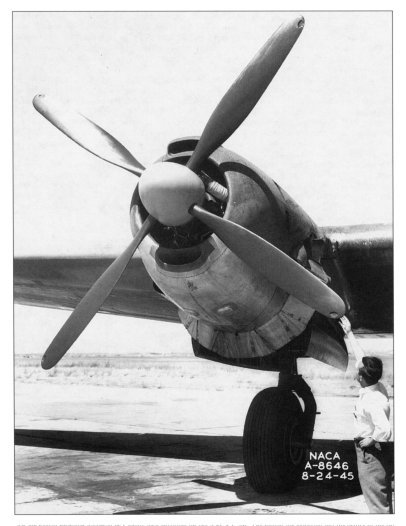

|

| An air heated propeller designed by Curtiss and installed on the NACA C-46. The heated air exhusted out the orifice at the tip of each blade. (NASA photo no. Ames A-8646). |

48 LEW RODERT, EPISTEMOLOGICAL LIAISON, AND THERMAL DE-ICING AT AMES

In September 1940, the Subcommittee reluctantly agreed to fund at $25,000 a year a research program led by Dr. Leo B. Kimball of the NBS. The Subcommittee after throwing out all sorts of speculation suggested Kimball start by building a window into his test stand so he could pass quick judgment on two existing de-icing systems. Then he should begin deliberate study of icing instrumentation, a temperature and pressure survey of the carburetor, and a process of fundamental research.

Kimball spent several months meticulously constructing a test stand for a Wright engine in his laboratory, trying to simulate rain and altitude. He studied the changing chemical composition of exhaust gases as octane and air combusted at various temperatures before starting on tests of alcohol injection, the first part of his stated task. When NACA pressed Kimball, in June 1941, to release some useful results, he looked through the observation window of his test stand and mimicked some rules of thumb Rodert had offered long ago: avoid any protuberances into the airflow, like bolt heads, and keep air flowing smoothly through cross sections that are geometrically similar.38 He then returned to his calibrations of measurements on icing, moisture, temperature, and throttle openings. In March 1942, Kimball was ready to shoot hot air into his test-stand carburetor, the second part of his research program.

By then Rodert, who had largely solved problems of wing and windshield

icing, began seeing carburetor de-icing as the reverse salient to making

an ice-impervious aircraft. Whenever asked to comment on Kimball's progress,

Rodert iterated that Kimball's strategy should be more like his:

I believe that it is better to employ trial-and-error methods in the search for a solution than to devote too much energy to analyzing the causes and effects of the many factors involved in the icing phenomenon. When an apparently satisfactory solution has been found, research leading to a complete understanding of the fundamentals may be required to perfect it. Such work is easily defined, because we then know what we are after.39

Rodert praised the more directed research program pursued by the

United Aircraft Corporation to improve its Pratt & Whitney engines.40

And he was encouraged when simple anti-icing tests were added to the Army-Navy

specifications for carburetors so the excellent NAF tunnel could begin

collecting data on induction icing. In February 1943, Rodert convinced

NACA headquarters to move Kimball's test stand to Minneapolis for studies

of the XB-17 engine induction system, and to build him a cowled engine

test stand that he could tow by car through the clouds along the Sierras.

In the meantime, Rodert's group determined that, as rules of thumb for

the C-46, they would avoid alcohol sprays, try resistance heating on carburetor

parts, and otherwise keep the intake stream at 90ºF for all its research

aircraft. Carburetor icing delayed none of the test flights in Minneapolis.

Yet in Rodert's haste to devise design rules of thumb using cut-and-try methods, he neglected more theoretical analysis of icing conditions and heat transfer. This approach did not go unchallenged. By the summer of 1944 the de-icing community would be rife with disagreements over how to specify a workable system and who should enjoy the flexibility to improve upon it.

FROM ENGINEERING SCIENCE TO BIG SCIENCE 49

Pushed into Theory

On a tour of southern California manufacturers in April 1943, Rodert was outraged to find that none were actually building thermal de-icing into production aircraft. After two years of expedited work, during which Rodert thought of little else, Ames had designed and proven de-icing for the B-24 and B-17, and had consulted on many more installations. AAF pilots had already flown the XB-24F over 200 hours in expedited service tests. Consolidated was already installing thermal de-icing systems into three Navy production aircraft: PBY-5 Catalinas, PB2Y-3 Coronados, and the PB4Y-1, the world's fastest flying boat.41 Consolidated had developed soft tooling for the B-24 retrofit, including a dimpled inner skin they found easier to fabricate. Consolidated was even installing the new heat exchangers, but for cabin hearing only. Even after public pronouncements that production B-24s sporting thermal de-icing would soon change, the face of air battle, the AAF was still retrofitting pneumatic de-icers on B-24s as they left the plant. When Rodert asked why, Consolidated blamed "red tape:" they were confused by conflicting specifications from the AAF Materiel Command, and thus had not prepared final production specifications for approval.42

If Rodert had thorns in his side, they were AAF Lt. Myron Tribus and Douglas Aircraft Company. Douglas was one of the first manufacturers to design hot wings, by adopting Rodert's 12A design to their XA-26 light bomber. But Douglas never liked exhaust gas or heat exchangers. Instead Douglas adapted a gasoline-burning cabin heater from its DC-3 and scaled it up for wing de-icing. Gasoline burners would be lighter, removable, less vulnerable to gun fire, and independent of engine failure. Burner temperature was more easily controlled, so excess heat would never weaken the wing structure. Further, Donglas wanted no exchangers blocking its ejector-type stack, which turned exhaust gas into Jet thrust. But Rodert's rules of thumb offered conflicting advice on how to calculate thermal requirements of gas burners. Rodert ran his early flights conservatively and got high numbers, and then had to convince manufacturers they could rise less heat. Without clearer calculations, by April 1941, Douglas still considered thermal heating "too experimental."43

Design politics within Douglas further encouraged them to pass blame to Rodert. Douglas charged the entire weight of thermal de-icing to its eqnipment gronp, which also bought pressurizers and air conditioners. They, in turn, wished to charge much of this weight back to the wing and structures group by emphasizing the role of inner skin in transmitting heat. The structures engineers refused any responsibility for the system, however, until the thermodynamics group specified more exactly what thermal stress de-icing imposed on the leading edge. And the thermodynamics group, because they specialized in heat transfer theory, wanted NACA to provide some kind of theory rather than just empirical design rules.44

Myron Tribus came to Rodert's attention in June 1942 when, as an undergraduate in Boelter's mechanical engineering laboratory, he clued in Douglas to another inconsistency in Rodert's heat transfer calculations. Tribus entered the Army Air Force in September 1942, and was sent to Wright Field to prepare specifications for de-icing systems. Wright Field engineers had been enthusiastic and compliant customers of Rodert's work. Rodert reported in November 1941 that Wright Field had agreed that all plans for de-icing "will be referred to me for approval until the Air Corps has developed a group of experienced

50 LEW RODERT, EPISTEMOLOGICAL LIAISON, AND THERMAL DE-ICING AT AMES

men in this field."45 Wright Field had virtually plagiarized the first draft of its specifications from BuAer's specification SR-105, issued in December 1941, which in turn borrowed Rodert's rules of thumb on heating.46

When Tribus arrived at Wright Field he declared the specifications too inflexible. Surely Rodert's wing design of ten to fifteen percent chord heating to 100ºF rise and exchanger design of 1000 BTUs per foot per hour, while good rules of thumb, would not fit all airfoils, wing structures, cruising speeds, or types of clouds. Air energy loss through tortuous ducting in the B-24 already made Tribus and Consolidated question Rodert's 1,000 BTU figure. Tribus knew Rodert's system worked, so instead he held up the uncertainty that the system might be lighter. Tribus wanted the specifications to state the temperature criteria needed to prevent icing "in air actually containing water droplets" then lend manufacturers flexibility in designing the wing ducting and heating systems. To do so, he wanted NACA to provide better data on the meteorological conditions for icing and better heat transfer calculations for wet air, like that in clouds.

Rodert, on the other hand, was in constant, personal contact with the manufacturers precisely because most wanted explicit design advice. Rodert had successfully designed new equipment of notable simplicity and good margins of error using the simpler dry-air calculations. He considered Tribus' preoccupation with wet-air both irrelevant, since weakening the ice adhesion bond was a sufficient concern, and too complex, since all air turned turbulent in the presence of water. Rodert further knew that Tribus harped on weight issues because he had a right to, and not because Rodert's design was too heavy. Many engineers in industry considered Rodert a peer, though quirky, and enjoyed mulling over aircraft design with him. This face-to-face contact, and not just the practical orientation, most distinguished Rodert's approach from NACA's traditional mode of encountering manufacturers which used the NACA committee structure as a filter.47 As Rodert expanded his program he told his bosses: "We hope that the NACA policy of permitting a close coordination of our work with the needs of the [AAF] Material Center, Bureau of Aeronautics, airline operators and manufacturers will continue."48

But Tribus considered such liaison his prerogative, and had access to the AAF job orders that Ames depended upon. Throughout 1943, DeFrance accepted more work on calculating wet-air heat transfers even though Rodert, with so many practical problems still to solve, considered such number-crunching an annoyance. This was good news to Douglas, which continued to complain about discrepancies in Rodert's calculations as a strategy for gaining greater freedom to design their gas-burning system. During 1943 Douglas had many planes with different types of de-icing equipment: C-74, SB2D-1, XTB2D-1, C-47, and C-54. Donald Douglas Jr. had invited Rodert to visit his plants every summer, but usually engaged Rodert on issues peripheral to his work on the hot wing-issues like how best to heat big aircraft cabins, how constant speed propellers could distinguish between friction drag from icing and normal drag from pitch change, and what to do about melted ice flowing backwards and clogging the ailerons.

At a public meeting of the American Society of Mechanical Engineers (ASME), Alun Jones spoke up about Douglas still specifying inadequate heat on the prototype DC-6.

FROM ENGINEERING SCIENCE TO BIG SCIENCE 51

Douglas had pushed ahead in specifying de-icing equipment based on icing conditions 20,000 feet altitude, 0ºF free air temperature, 0.5 grams per cubic meter liquid water content, and 205 mph true airspeed rather than simple temperature rise. Douglas and Stewart-Warner had announced that they designed a burner that weighed twenty-two pounds, put out 240,000 BTUs per hour, with a tungsten igniter that worked at any altitude. United Air Lines intended to buy the DC-6, and sided with Jones. United pilots had flown Ames' C-46, and wanted their procurement contract for the DC-6 to specify similar performance. Douglas, however, noted that the Ames' reports never specified this performance data, but only design criteria.

So Rodert and Jones asked DeFrance for time to prepare a text on thermal requirements for de-icing using existing dry-air calculations. DeFrance said no. Manufacturers already understood dry air work; to stay on the cutting edge Ames had to move into the more controversial wet air work. When George Lewis of NACA headquarters asked Rodert and Jones to prepare a manual of standardized data on heat exchanger performance, DeFrance protected them, saying their time would be wasted writing manuals for junior engineers. Captain William A. Bennett, Jr., the AAF Materiel Command Liaison Officer to Ames, asked DeFrance to allow him to release preliminary data from Ames exchanger tests. DeFrance agreed, and also asked Boelter to spend the summer revising reports into "The Comparative Performance of Several Exhaust Gas-Air Heat Exchangers." (Rodert congratulated Consolidated Vultee Aircraft Corporation, in June 1944, when they took the initiative of releasing a Thermodynamics Manual summarizing Ames data and design experience.)

DeFrance seemed especially sensitive to what roles NACA could play in directing the industry. He also sensed that Rodert's zeal had raised some hackles. NACA had indeed proved that thermal de-icing held promise, and generated some excellent design rules of thumb. But even the urgency of wartime should not allow Rodert to intrude on the procurement responsibilities of young Lt. Tribus. The AAF had begun giving icing research contracts to more compliant institutions. Nor did urgency allow NACA to come between manufacturers and their customers. DeFrance knew the Ames group would need to shift its focus to more theoretical issues of icing and heat transfer, and encouraged Rodert and Jones to redefine their research agenda before others forced them to.

For example, the AAF announced in April 1943 that it would assume control of the Minneapolis operations, rename it the Ice Research Base (IRB), and expand into a hangar not needed by the Air Transport Command. When the base reopened that September all testing was directed by those engineers in the AAF Engineering Division who needed to standardize acceptance tests, write manuals and technical orders, and approve production drawings of de-icing equipment for twelve new aircraft. Rodert sat out the 1943-44 testing season but kept the XB-24F at Ames until December. DeFrance sent Carr Neel to represent NACA and run the IRB "experimental program," which Tribus had restricted to flight tests in the C-46 "icing lab."49 Rodert waited until January 1944 to release the C-46 to the Ice Research Base, then had it returned to him the following month.

The C-46 Icing Laboratory

Because Ames had built into the C-46 very complete de-icing equipment, they could fly it into the most severe icing conditions and collect data. For the next two years, Ames pilots would fly the C-46 on a triangle route-from San Francisco northward toward Seattle and inland toward Salt Lake City. Local newspapers often reported

52 LEW RODERT, EPISTEMOLOGICAL LIAISON, AND THERMAL DE-ICING AT AMES

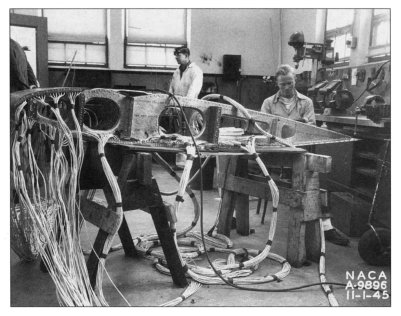

|

| A laboratory test section of an electrically-heated airfoil for the C-46, in November 1945, with the thermocouples and nichrome electrical heating elements already installed. (NASA photo no. Ames A-9896). |

on passengers stuck weather-bound at an airport, only to see the C-46 barrel through the clouds to a safe landing. Ames rescarch took on a different hue once centered on this C-46.

Beginning in 1944 they focused on statistical definitions of the meteorological conditions for icing. Rodert had previously dismissed all work on icing indicators, arrogantly expecting his thermal system to work so naturally that pilots had no need to know when they encountered icing. Furthermore, the only practical indicators measured accumulation of ice in order to activate pneumatic de-icers, even though pilots agitated for an indicator that measured the rate of accumulation so they knew when to fly out of icing clouds. 50 Rodert avoided the debate between accumulation versus rate of accumulation indicators to wait for research on measuring more "fundamental" icing conditions: liquid water content of clouds, free air temperature, droplet size, and the distribution of droplet sizes. (Small drops would deflect around the wing by boundary layers; larger drops would slam into the wing.)

Free-air temperature was tough enough to measure; doing so in a cloud of unknown moisture content evoked special ingenuity. Jones directed the work on icing

FROM ENGINEERING SCIENCE TO BIG SCIENCE 53

indicators both what they indicated and how well while Weather Bureau meteorologist William Lewis, working with the NACA Subcommittee on Meteorological Problems, suggested hypotheses on which data best portended icing. J.K. Hardy, the British wartime representative and an impartial observer to the Rodert-Tribus dispute, offered to stay with the Ames group through 1947 and use this wet-air data to work up a de-icing theory. Hardy began by calculating the dissipation of heat in wet air from Rodert's dry-air equations, then devised a theory to predict the de-icing performance of the C-46. NACA engineers devised an "optical rainbow recorder" to provide continuous measurement of the water content in clouds, a dew-point recorder and drop size recorders in their search for "further accuracy and simultaneous, continuous and instantaneous recording of all meteorological data."51 Jones considered it especially challenging work. "The determination of the amount of free water in a cubic foot of cloud through which you are flying at 150 to 200 m.p.h.," noted Jones, "is a problem to be approached with respect."52

They began collecting data on icing in other parts of the world, like that encountered by the American-run Chinese National Airways ferrying cargo from India to China over the Himalayan Hump. Icing conditions stretched from 12,000 to 16,000 feet, so a DC-3 could not drop below or climb above it. Ice often formed four inches thick, completely blocking the windshield, and brought down more than 100 transport aircraft flying the Hump during the war, including nine in one day.

Rodert, whose reputation continued to spread, spent more time on ill-defined icing issues-like heat transfer in Navy airships, de-icing aircraft carrier decks, using a static electric field to repulse cloud droplets, protecting the protruding landing lights on the B-17, and frost on cabin windows. And he made one last effort at thermal de-icing the 12A with waste exhaust gas. This time he mixed 15 percent exhaust directly with air, to a temperature of 300ºF, and then pumped it through the thin integral skin along the wing leading edge. This avoided the air pressure problems of heat exchangers, minimized maintenance problems and corrosive acids of pure exhaust, and saved the weight of gasoline burners. But it still produced unacceptable levels of condensation.

By the close of the war most manufacturers were set on using thermal de-icing, but with gasoline burners and methods Rodert had earlier bet against. Most postwar transport aircraft like the Boeing B-50 Stratocruiser, the Douglas DC-6, the Martin 202 carried thermo-electric propellers, single-pane non-electrostatic windshields with very hot air blasts on the outside, and hot wings with gasoline-burning heaters built into the nacelles.53 Stewart-Warner's South Wind heater, now improved, could put out 300,000 BTUs per hour from just 2.8 gallons of engine gasoline. Only Consolidated was using NACA-type heat exchangers, on its C-99 and model 39 cargo aircraft, despite trouble with its air-discharge valves. Still, the airlines considered Rodert a hero for calling manufacturers' results into question and expediting development across the board.

Rodert's ties with the airlines improved as the war came to a close. The chief engineer from Pennsylvania-Central Airlines visited Ames and noted that PCA lost $78,000 in the first quarter of 1944 alone by holding aircraft on the ground. Most airlines still suffered 20 percent downtime during the winter months. He was planning on retrofitting

54 LEW RODERT, EPISTEMOLOGICAL LIAISON, AND THERMAL DE-ICING AT AMES

thermal de-icing on all his aircraft and wanted NACA's advice. By 1944, most airlines had specified thermal de-icing equipment on their new aircraft and many were retrofitting it on their old aircraft. After several airlines asked for permission to fly the C-46, Rodert noted "the plans for the future of the airlines may serve as a good guide for expansion of NACA research facilities."54 DeFrance planned a conference on thermal de-icing for the airlines that, to encourage more open discussion, would exclude the military.

Meanwhile, Rodert's relations with the AAF deteriorated. Rather than himself collect the data and write the specifications he thought so vital, Tribus continued to blame NACA for not doing so: "Designers, in short, are designing heated wings on the basis of very general information derived from experiments, which have been neither analyzed nor correlated." DeFrarice retorted: "The Laboratory believes that a rigorous analytical treatment of the icing phenomenon is desirable from an academic viewpoint; however ... most questions originate from a reluctance to make the required changes to an existing airplane or to install adequate heating capacity in a new airplane, and that the inquirer is usually seeking an escape from the design requirements shown necessary by our data."55

Demobilizing Icing Research

The conflict between Tribus and Rodert came to a head in January 1945, when Tribus publicly presented a paper excerpting NACA reports.56 Tribus had written the paper back in July 1943, even as he pressed Rodert to hurry the release of the written data that manufacturers clamored for. Rodert's report writing, however, was slowed by new research, the usually slow NACA peer review process, and Army Air Forces classification. Tribus' paper was among the first icing reports downgraded from "confidential" to "restricted." Tribus then manipulated the system to get his paper completely declassified for the January 1945 meeting of the Society of Automotive Engineers, a meeting at which Rodert introduced him, and the paper for which Tribus won the Society's Wright Brothers Medal. Rodert was furious. DeFrance argued Rodert's case, contending that Rodert had dedicated himself to this work only to be robbed of tribute. "Due to the classification imposed on ice-prevention research" by the AAF, DeFrance wrote, whenever Rodert presented papers he "was required to speak only in general terms thereby impairing the quality and value of his paper. "57 Rodert was further incensed that Tribus would claim credit for work-on dry air heating requirements and exchanger design-he routinely belittled. Rodert saw his group suffer a morale decline from laboring so hard in obscurity. Thereafter, NACA more carefully claimed credit for their work on thermal de-icing, and Rodert and Jones found time

FROM ENGINEERING SCIENCE TO BIG SCIENCE 55

to finish reports of wartime work .58 (Tribus, meanwhile, after pressing his seniors so hard for "A Theory of Heat Anti-Icing," returned for a master's degree at war's end rather than entering industry, and remained an academic his entire career.)

Rodert left Ames in September 1945, to cash in on the growing demand for heat exchangers he had created. He joined the Indianapolis-based South Wind Division of Stewart-Warner Corporation, with whom he had worked closely in the past, and remained active with NACA as chair of the de-icing committee.

But within a year he was back with NACA, to head the growing flight research branch at the NACA Aircraft Engine Research Laboratory in Cleveland. As early as January 1940 Rodert had outlined a program of engine and propeller icing research that was later written into the laboratory's agenda.59 By VJ Day, the Cleveland laboratory had forty-nine people engaged in icing research, compared with thirty-two at Ames. There Rodert had three research aircraft at his disposal. A B-25 was calibrated so that they could switch off one part of the de-icing system, like the propeller, and then measure how icing there affected total aircraft performance. A B-24 had special installations for tests of windshields and antenna-placing them at various angles and measuring both drag and proclivity to icing. These flight tests mirrored many done during the war, except they were done with much greater precision.

Rodert's flight research complemented icing tunnel research under the direction of Wilson H. Hunter, former chief of Goodrich's icing tunnel. NACA built the world's largest refrigeration plant to serve Cleveland's new high-altitude wind tunnel, and the plant had surplus chilling for a smaller six by nine foot icing research tunnel. Winds at velocities up to 320 mph passed through a heat exchanger that cooled it down to minus sixty-five degrees, when a spray bar shot water into the refrigerated airstream. The tunnel had three sections-one for propellers, one for rotary wings, and one for engines, wings, windshields, and antennas. While droplet size in the tunnel was ten times too large to truly simulate natural icing, the Cleveland group made good use of it. They designed an inertial separator for carburetor deicing, essentially a curve in the intake housing that divided heavier, moisture-laden air from the drier air that then entered the engine. They also analyzed the trajectory of a water-drop around an airfoil, to understand how water intercepted by a heated body was dispersed.